Introduction:

Glass Reinforced Plastic (GRP) tanks are innovative water storage solutions that amalgamate durability with flexibility. Crafted from composite materials, GRP tanks are distinguished for their robustness, resistance to corrosion, and adaptability to various climates and environments.

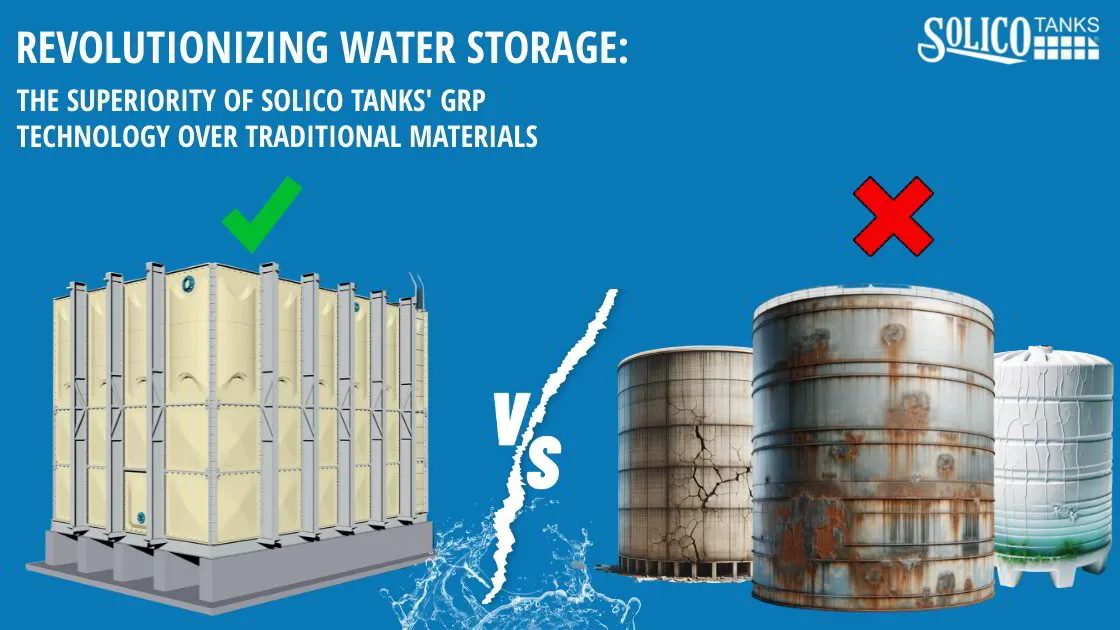

Their significance in water storage cannot be overstated, as they represent a critical advancement over traditional materials like steel, concrete, and plastic. This comprehensive analysis will explore how GRP tanks stand out in terms of corrosion and chemical resistance, prevention of bacterial growth, structural integrity, and ease of installation and maintenance.

The versatility in customization, superior temperature stability, and overall cost-effectiveness will be examined in contrast to their counterparts, showcasing why GRP tanks are increasingly becoming the preferred choice for sustainable water storage in diverse industries and communities worldwide.

Manufacturing of GRP Tanks:

The manufacturing of GRP tanks is a sophisticated process that begins with the selection of quality materials, including high-strength glass fibers and durable resin. These are combined using a specialized technique called Sheet Molding Compound (SMC) production.

In this process, the glass fibers are precision-cut and then blended with the resin to create a strong, flexible, and corrosion-resistant material. The SMC is then layered and compressed under heat and high pressure to form the robust panels that constitute the GRP tank.

This method ensures a uniform composition and thickness, resulting in tanks that offer unparalleled structural stability and longevity.

The end product is a tank that provides a safe, secure, and hygienic solution for water storage, tailored to meet the needs of diverse applications, from residential complexes to industrial settings.

Comparative Analysis of Tank Types:

Corrosion Resistance:

GRP (Glass Reinforced Plastic) tanks offer exceptional corrosion resistance compared to conventional materials like steel. The unique composition of GRP, which embeds fine glass fibers in a resin matrix, creates a non-corrosive material unaffected by rust and chemical degradation.

This inherent resistance extends the tank's lifespan, maintaining structural integrity even under harsh environmental conditions. In contrast, steel tanks are prone to rust, plastic tanks can degrade with UV exposure, and concrete tanks may suffer from leaching and cracks. GRP tanks' ability to withstand a wide range of pH levels and temperatures without deterioration positions them as a superior choice for long-term water storage in a variety of settings.

Chemical Resistance:

GRP tanks exhibit superior chemical resistance, making them ideal for industrial applications where exposure to corrosive substances is common. Unlike steel tanks, which can corrode and leach into the stored liquid, GRP materials remain inert, ensuring that chemicals do not compromise the tank structure or contaminate the contents.

Plastic tanks, while also resistant to some chemicals, can degrade under certain conditions, and concrete tanks are vulnerable to chemical attacks that can erode the material.

GRP tanks maintain their integrity over time, providing a safe and durable solution for storing a wide range of chemicals.

Bacteria and Algae Resistance:

GRP tanks offer significant hygienic benefits, particularly resistance to bacteria and algae growth. Their non-porous nature and smooth internal surface prevent microorganisms from adhering and proliferating, unlike concrete or steel tanks, which may have crevices and rough surfaces conducive to biofilm formation.

Plastic tanks, while somewhat resistant, can still be susceptible under certain conditions. GRP tanks, treated with UV-resistant materials, impede algae growth, which relies on sunlight, ensuring that water stored in GRP tanks remains clean and safe for a longer period, making them a preferable choice for potable water storage and sensitive industrial processes.

Strength and Reliability:

GRP tanks are renowned for their strength and reliability, outperforming traditional materials like steel, concrete, and plastic in durability and longevity. Their unique composition allows them to resist harsh environmental conditions, mechanical impacts, and structural stress, leading to a longer service life with minimal maintenance.

GRP's material properties ensure it does not degrade like steel, which rusts, or concrete, which can crack and leak. Their robust construction typically offers a lifespan that can extend up to several decades, providing a cost-effective solution in water storage that requires less frequent replacement or repair.

Transportation and Installation:

GRP tanks boast significant advantages in terms of transportation and installation when compared to their steel, plastic, and concrete counterparts.

The lightweight nature of GRP material makes it much easier and more cost-effective to transport. Additionally, GRP tanks can be manufactured in modular sections, allowing for convenient on-site assembly.

This modular design reduces the need for heavy lifting equipment and simplifies the installation process, cutting down on both time and labor costs. The flexibility of GRP also allows for installation in challenging locations without compromising the tank’s integrity or performance.

Maintenance:

GRP tanks are renowned for their low maintenance requirements compared to other types of tanks. Their non-corrosive nature means that they do not require regular painting or rust prevention treatments.

The smooth interior surface of GRP tanks prevents algae growth and the buildup of other substances, which reduces the frequency and intensity of cleaning needed. Any required maintenance is often simple and can be performed without the need for specialized equipment.

This simplicity extends the lifespan of the tanks and leads to significant cost savings over time, with less downtime for repairs or replacement.

Customization, Relocatability and Flexibility:

GRP tanks offer unparalleled customization, relocatability, and flexibility. They can be tailored to fit specific space requirements and shapes, making them suitable for a wide range of applications, from urban settings to remote locations.

The modular design of GRP tanks allows for easy disassembly and reassembly, facilitating relocation as needs change. This flexibility, coupled with their lightweight nature, makes them a versatile choice for both temporary and permanent installations, adapting seamlessly to evolving storage demands and site conditions.

Temperature Stability:

GRP tanks excel in temperature stability due to their superior insulation properties. They are designed to withstand a wide range of temperatures, making them suitable for various climatic conditions.

The material's thermal resistance ensures that the water inside maintains a consistent temperature, reducing the likelihood of damage from freezing or overheating. This temperature resilience is particularly beneficial in applications where maintaining a specific water temperature is crucial, such as in certain industrial processes or in regions with extreme weather conditions.

The insulation properties of GRP tanks also contribute to energy efficiency, as less energy is required to heat or cool the stored water.

Case Studies and Data:

Real-world case studies and statistical evidence highlight the superior performance of GRP tanks. For instance, a large-scale water storage project in a harsh desert climate utilized GRP tanks, which demonstrated exceptional durability and low maintenance over several years, outperforming traditional materials.

Another study in a coastal region showed that GRP tanks maintained their structural integrity and water quality despite exposure to saline air, which would typically corrode metal tanks. These examples underscore the practical and long-term benefits of GRP tanks in diverse environmental conditions.

Global Perspective:

The adoption of GRP tanks is gaining momentum globally, with regions recognizing their benefits in various applications.

In arid climates, GRP tanks are chosen for their resistance to harsh conditions, while in urban settings, their adaptability and space efficiency make them ideal. Coastal areas value GRP tanks for their ability to withstand corrosive marine environments.

This widespread acceptance underscores the versatility of GRP tanks, making them a preferred choice for water storage needs across diverse geographical and climatic conditions.

Conclusion:

In summary, GRP tanks from Solico Tanks stand out for their corrosion resistance, chemical durability, hygiene, structural strength, ease of transport and installation, low maintenance, customization, and temperature stability.

These features make them superior to steel, plastic, and concrete tanks. Globally, diverse regions are adopting GRP tanks for their versatility and resilience in various environmental conditions.

Solico Tanks, a leader in this field, offers top-tier GRP tank solutions. We invite you to choose Solico Tanks for reliable, sustainable, and efficient water storage solutions. Contact us to explore how we can meet your water storage needs.